Summary: In-line centrifugal fans are great air moving devices that can effectively move the air from one point to another. They are great when it comes to moving air very quickly and efficiently, but while using less energy than other types of fans. This amazing efficiency enables the users to enjoy convenient airflow in their rooms without experiencing increased electricity bills.

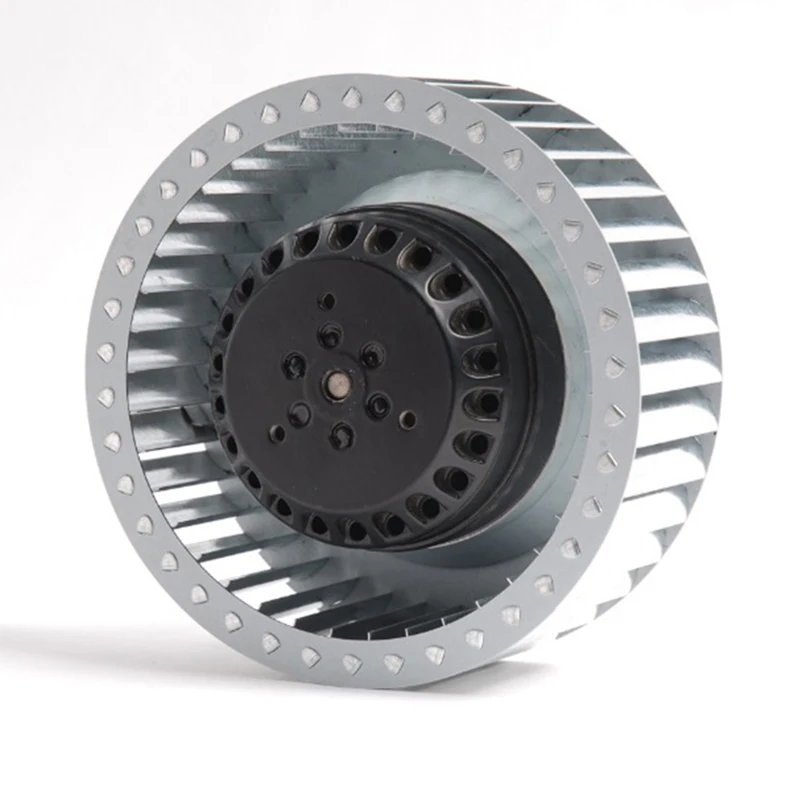

In-Line Centrifugal Fans work around a central spinning wheel which has blades, to manage air flow. The rotation of the fan is what creates a pressure difference in comparison to abroad so it pulls air into the middle and once again simply sends it back out on the other side. This unconventional design allows the in-line centrifugal fans to easily manoeuvre within ducts and tight spaces where air has to be moved over long distances or confined areas.

It consumes very less power for being so efficient, there are other positive attributes of in-line centrifugal fans. Their most unique feature is that the fan wheel spins inside of itself, making it one of the quietest fans available. In addition, the two-speed fans can be easily installed with a variety of mount configurations and are equally effective in residential or commercial applications.

In relation to durability, in-line centrifugal fans are designed for long lasting operation that minimize break downs and frequent repair. The dependability of these in-line centrifugal fans makes sure that people will be able to trust their operation whenever they are needed.

Moreover, these fans provide the most necessary part of a room to maintain temperature. Some ideas include the ability to improve air circulation for a cooling or heating effect. This is especially useful in spaces that are difficult to heat or cool with a conventional system.

In addition, in-line centrifugal fans are more suitable for producing high-volume airflow and can therefore help to circulate large amounts of air quickly. These are widely used situations such as cooling in industrial tools from large structures to sporting venues, or other case uses like manufacturing plants and wastewater treatment facilities.

Induct fans also are often incorporated into HVAC systems to assist in heating, ventilation and air conditioning operations. Air Regulation and Pollution Control: These line fans are used to regulate temperature of a place by directing the airflow through duct or help in removing pollutants so that air quality enhances.

Beron motor in line centrifugal fan time 3-7 days, 7-7 days small quantity orders, and triers orders. within 25 days for large orders. We offers services more than 5000 customers around globe and exports to over 50 countries.

Beron motor producer covers in line centrifugal fan square feet two factory centers. Beron motor 3 product lines, which include 2000 models as well 10000 types spare parts. Beron motor 1 laboratory located well-known university.

Beron Motor's main product EC DC AC in line centrifugal fan Rotor Fans that Full ranges. products widely used Fresh airs systems, heating, air conditioning ,refrigeration, airs purifications, telecommunications, electric powers etc.

Beron motors is certified through CE in line centrifugal fan and UL CCC SGS and others certifications. Additionally, we have a Wind tunnels as well as a sounds test lab.