As the flow is different then the back ward inclined centrifugal fans varies and reduced too.

This blog deals with the world of backward inclined centrifugal fans - those hidden blades whirring silently in the background to ensure that foul air is removed from your building, while also maintaining a cozy thermal environment. They are often be in use to keep comfort and welfare systems like HVAC employed. So in this trail of discoveries, let us unveil the sophisticated construction and process involved by a backward inclined centrifugal fan to know what it does, why they are advantageous for applications that include both industrial as well consumption sectors like recreational indoor facilities including monthly maintenance procedures implemented on such designs leading up to conclusion on knowing which is best suited ideal.

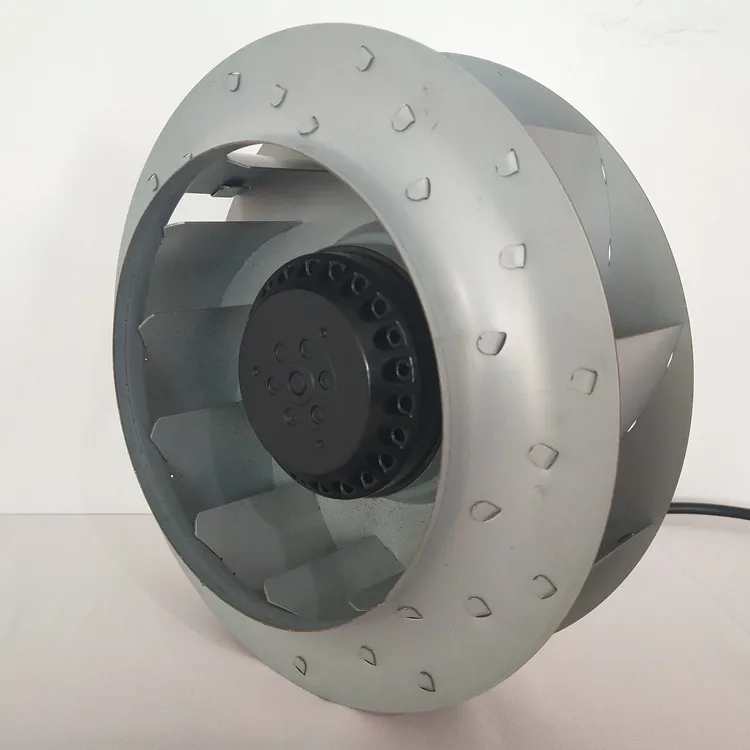

The Backward inclined centrifugal fans get a break in our HVAC systems helping to push air through ducts right where it is needed. The blades also feature an innovative design, with curved and backward-slanted air fans that are very different from the familiar forward-facing designs. This unique design allows the blades to draw air in and expel it on their backside, making them a type of fan called backward inclined centrifugal.

These pressure resistant aerodynamically designed fans are equipped with slanted and curved blades, which not only produce excellent air flow but also make sure that fan can bear the loads of enough challenging applications. This is particularly good for use with HVAC system, whose fans have to move air long distances and through ductwork. Unlinke other model, Backward Inclined Centrifugal Fans could work handling much higher capacities and moving more air without exceeding recommended temperature limits.

Reverse Curved Centrifugal Fans for HVAC Systems First, these are high air flow ceiling fans which makes them ideal replacements in larger buildings or rooms that required the increased circulation of airflow. Furthermore, they perform this procedure in higher energy efficiency; hence less power consumption. On the other hand, these fans offer all the advantages of fine air flow control and targeted ventilation to compartmentalized areas.

Operations on both heating and cooling systems, as well as industrial processes everywhere above ventilation devices people place here and there. General Use- Industrial facilities such as manufacturing plants, warehouses or any application that requires a high airflow capacity can benefit bebefit from backward inclined centrifugal fans. They use to adorn different the commercial areas like malls, corporate offices and hospitals etc along with providing a pleasing temperature even under these too large fans available for keeps.

Backward inclined centrifugal fans are guaranteed to work when the right maintenance is applied. One of the use ways to perform this maintenance is for you will just go ahead and check if fan blades are clear. Because the blades can give way to dirt and dust, which in turn inhibits airflow efficiency

Don't forget to check the belt that operates your fan - if it is worn out or loose, then its efficiency also goes down. Moreover, it will also extend the lifespan of your fan by lubricating them when with other mechanical parts. You can identify quickly any wear or damage by doing periodic service that must be replaced immediately when necessary.

Using Backward Inclined Centrifugal Fans to Boost Energy Efficiency and Air Flow Control

Environmentally friendly, refined airflow control - backward inclined radial blade centrifugal fans offer the best of both worlds due to their energy efficient performance. This in turn leads to less power consumption, which saves your electricity bills and also is environmental friendly as they consume much lower energy compared to the conventional fans. Further, to the extent that fans are used for air handling equipments, fan speed control devices allows a degree of flexibility regarding when and how in airflow can be achieved. The similar flexibility also improves the accuracy of Environmental levels in Buildings giving more comfort to its occupants.

Because there are so many different backward inclined centrifugal fans on the market, choosing the right one can be quite a challenge. What to think about: the square footage of your area, how much air flow you need and what type of duct system are currently (referring here is kind). Although it is not necessary to utilize a lot of air, you should decide on an energy-efficient fan with very low maintenance requirements.

In conclusion, the backward inclined centrifugal fan is a critical element to HVAC systems and echoes across various industries. Product an innovative design that is better at moving air and uses less power than other fans, this makes it a smarter buy for eco-friendly living. To keep these fans running at top speed, makes a need to gin up on why you would only buy such robust mistral-operating fan.

Beron motors is certified through CE ROHS The motor is certified by CE ROHS, UL CCC SGS and others certifications. Additionally, we have a winds tunnel and backward inclined centrifugal fan.

Beron Motor promises samples time within 2-3days. Trials and small quantity orders will backward inclined centrifugal fan. Mass orders delivered within 25 days. We exports our products over 50 countries, and offers services over 5000 customers worldwide.

Beron motor manufacturer backward inclined centrifugal fan 15000 square meters two factory centers. Beron motor manufacturer three product lines, including than 2000 models more 10000 different kinds spare components accessories can meet every customer's needs complete terms. Beron Motor laboratory located renowned university.

Beron Motor's backward inclined centrifugal fan product line EC DC AC External Rotor Fans Full Ranges. products widely used Fresh air system, heating, air conditioning ,refrigerations, air purifications, telecommunications, electric power etc.